PROCESS AND ENERGY AUDIT: AUDIT TO UNLOCK YOUR PLANT POTENTIAL :: ACTIVITY_PROCESS ANALYSIS-->OUTCOME_ROAD MAP FOR OPTIMIZATION

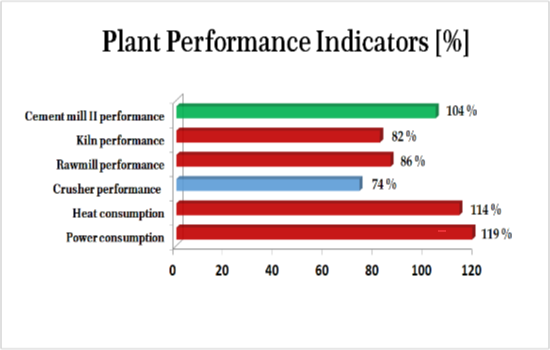

A detailed audit is an ideal way for independent assessment of performance of a cement plant, and for identifying performance gaps, bottlenecks and opportunities for improvement.

We offer audits that evaluate present performance and recommend actions to improve your cement manufacturing business. We help you to assess and optimize your current equipment and identify areas that may require upgrades or modifications. Sometimes small adjustments of equipment or processes can deliver big benefits.

Identifying constraints in your plant operation and finding potential areas of improvement are important to every business. Even an already highly performing plant can always have enough scope for further improvements. Even if you think that an upgrade or modification is needed, you might be unsure about where to focus your investment and how to take into consideration all the factors that impact your processes.

Comprehensive Audit and Onsite Audit Training [PROCESS-ENERGY AUDIT]

One-week classroom training on:

How to use portable instruments at site- correct procedure.

Procedure of conducting process audit.

Details of process measurements in each section.

Process calculations for determination of KPIs [At the end of audit: Optional].

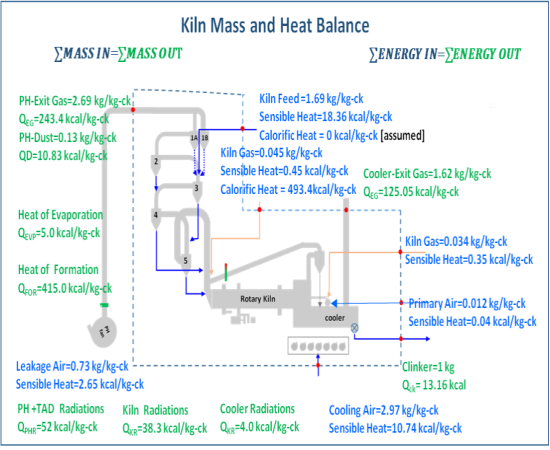

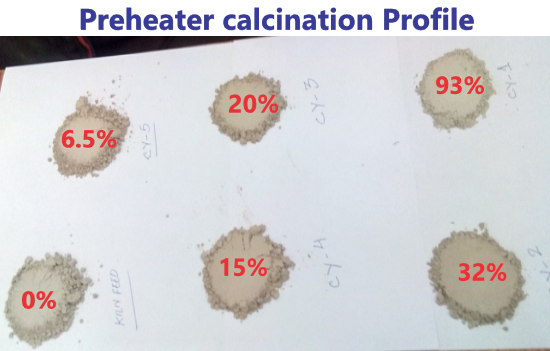

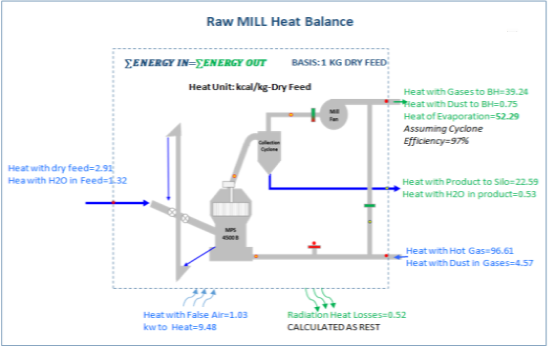

Comprehensive Audit: Crusher audit, Raw mill audit, Coal mill audit, Pyro section audit, and Cement mill audit

Comprehensive Audit + Classroom Training is designed to train plant people, and enhance their knowledge and skills to the level so that they can conduct the detailed audit of plant independently whenever required. It includes training, plant audit and detailed audit report from cementindusneed.

Comprehensive Audit [PROCESS-ENERGY AUDIT]

Comprehensive Audit: Crusher audit, Raw mill audit, Coal mill audit, Pyro section audit, and Cement mill audit.

It includes detailed plant audit and detailed audit report from cementindusneed.

Section Specific Audit [PROCESS-ENERGY AUDIT]

Section Specific Audit: Detailed audit of any of the sections or equipments of plant like Crusher, Raw mill, Coal mill, Pyro section, Cement mill, Process fans, Bag Filters/houses etc.

It includes detailed plant audit of specific section/equipment[s] and detailed audit report of the same from cementindusneed.

In addition to this, we feel pleasure to guide our customers to implement the recommendations we made in audit report. We believe that audits are to identify the optimization potential in plant, and actual improvements are achieved only with appropriate action plan, so we provide a clear road-map with milestones in audit report to make it easy for plant people to follow.

Work flow of Audit

For any type of audit, the process typically follows workflow:

- Pre-audit Discussion

- Audit proposal [Scope definition and terms of agreement].

- Audit preparation. [Site visit to review measurement points, instrument calibrations etc].

- Onsite audit

- Audit report

- Follow Discussion and support