Drying of moisture in raw materials is required for effective grinding and subsequent handling of raw meal. This is achieved normally by ducting part of the kiln exhaust gas through the mill with inlet temperatures of up to 320°C. However, when starting from cold, when hot gases are not available from kiln, Hot gas is provided by Oil fired Hot Air Generators (HAG) in Raw Mill and Coal Mill. Care should be taken in coal mills due to risk of fire and or explosion when hot air is used in the system. Inertization of coal mill circuit and fine coal bins with CO2, N2 or CO2+N2 to replace O2 which promotes spontaneous ignition of fine coal.

Vertical roller mills can typically handle an aggregate moisture of up to 20% in raw materials and consumes about 30% less power in grinding. Hence it is commonly preferred for grinding operation in new plants of higher capacities. However, many ball mills are still in use. Roll presses are also used in, particularly in upgrading existing ball mill circuits as pre-grinders to increase production or to reduce specific power consumption in grinding operation. Ball mills for cement raw material and coal equipped with a drying compartment adequately air swept with hot gas (2.5-3.5M/sec above the ball charge), can handle moisture about 8%. Fully air- swept mills (5-6M/sec) can dry up to 12-14% moisture.

Grinding Operation Objectives and KPIs: Highly energy intensive unit operation of size reduction in cement industry is intended to provide a homogeneous, dry (<0.5% moisture) and super fine (10-20% residue on 90-micron sieve) raw meal powder for clinkerization process in kiln (Dry Process). Grinding operation is monitored for following parameters to ensure objectivity and economy of operation.

Chemical analysis of raw mix, generally on hourly basis.

Product fineness (Residues) on 90-micron and 212-micron sieves.

Feed moisture, % and Product moisture, %

Production rate, tonnes/hour

Operating hours as run factor in %

Specific power consumption (SPC) kWh/tonne.

Specific Wear rate, g/t (checked during maintenance of mills)

Chemical analysis of +170# fraction to find separation factor (Done as and when required). The coarse (+170#) fraction may be lime-rich or, more likely, silica-rich relative to the total sample but should show constant bias. Coarse particles should be limited to avoid burning problems:

Silica >200μ Not more than 0.5% of KF

90-200μ Not more than 1.0% of KF

45μ Not more than 2.0% of KF

Calcite >125μ Not more than 5.0% of KF

Grindability and Power Consumption.

Among various theories of comminution, most commonly accepted which is relevant to ball /tube mills is Bond's theory, which states that power input in comminution process is proportional to the surface generated in the process and the grindability of the material. To measure grindability, Bond developed 'Bond's Work Index' (BWI), a 'test mill' and a testing procedure for WI. With the help of this we can work out power required to grind a material from a given feed size to a product of given fineness.

Other index known as 'Hardgrove Index" is also used to scale grindability of materials, particularly coal. Hardgrove index is commonly used to determine power requirements of vertical coal mills.

Relation between BWI and Hardgrove Index can be described by the following equation.

B.W.I. = 435/(H.G.I.)0.91

GRINDING MILLS

Mills will be selected according to type most suitable for required capacity and duty and for overall power consumption. From Process point of view grinding operation in cement plants may be performed with one of the following ways.

Wet Grinding: Open circuit Ball mill or closed circuit Ball mill

Dry Grinding: Open circuit Ball mill, closed circuit Ball mill, vertical roller mill, Roll Press or Roll press in circuit with ball mill

However, it would be seen that the most significant process and types used for raw material grinding operations in modern cement industry are:

Process: Dry Closed circuit dry-grinding

Type of mill:

- Ball and tube mills.

- Vertical Roller Mills (VRM).

- Horizontal roller mill (Roll Press)

- Roller press with Ball mill.

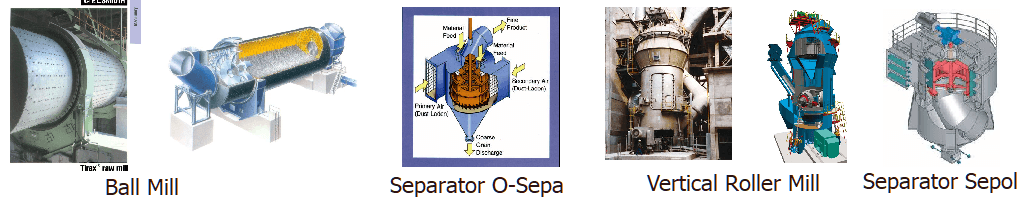

Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 70-80% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills. Closed circuit ball mill with two compartments for coarse and fine grinding and a drying compartment with lifters are generally found in cement plants for raw material grinding. Compartments (filled with grinding media) are divided by a double diaphragm with flow control to utilize maximum mill length for effective grinding.

Grinding media contain balls of different sizes in designed proportions with large sizes in feed end and small sizes in discharge end. About 27 to 35 % volume of mill is filled with grinding media. Equilibrium charge is that charge where compensation for wear can be done by balls of one size only usually the largest size in the compartment. Grinding media could be made of forged steel, cast steel or even cast iron. To economize grinding media consumption, presently grinding media used are high chrome steel balls.

Mill shell is lined with lining plates to protect it from wear, high chrome steel liners are now commonly preferred to give longer life. Lifting liners are used to enhance impact in first compartment, where coarse grinding is dominated by impact. In second compartment which is longer in size (L>1.5D), classifying liners are used to ensure media classification along the length of mill with large size balls near mid partition and smaller balls at mill discharge end.

Ball mills are either 'air swept' or of 'bucket elevator' type. In air swept ball mills, material is swept out of the mill by hot air /gas of significant velocity (5-6 m/s), through separator and coarse fraction is returned to the system for regrinding. In case of bucket elevator mills (gravity discharge mills), ground material is taken by conveyors to a separator where coarse was returned to the mill and fine sent to cyclone separator or bag filter for collection.

Different drive arrangement for ball mills are in existence. Commonly existing arrangement is mill drives with a girth gear and a pinion driven by motor with a gear box. Larger mills have a twin drives of half the ratings on either side of same girth gear. In central drive arrangement both the girth gear and pinion are avoided by connecting gear box output shaft directly to mill.

Closed circuit ball mills are existing with all types of separators () grit, mechanical and high efficiency in cement industries. Presently high efficiency separators are common to achieve maximum energy optimization. Brief description of separators is presented at the end.

Primary Ball mill controls are:

Mill drive power or mill differential pressure to control mill feed rate.

Mill Sound level to control filling level inside mill with feed rate.

Inlet gas temperature.

Outlet gas temperature.

Outlet gas flow determined from mill inlet and outlet drafts or flow meters installed.

Vertical Roller Mills. In Vertical Roller mill 2 - 4 rollers (lined with replaceable liners) turning on their axles press on a rotating grinding table (lined with replaceable liners) mounted on the yoke of a gear box. Pressure is exerted hydraulically. This mill also has a built in high efficiency separator above the rollers to reduce circulation loads and consequently reducing differential pressure across the mill. It also has an annular ring which admits air at velocity as high as 85 m /sec. Feed material is directed onto the center of the table and is thrown outward by rotation under the rollers by centrifugal action. Material gets partially ground and as it falls over the edge of the table, where it is picked up by hot air /gas, and is separated into coarse fraction falling back on grinding table and fine fraction is carried with air to product collector.

With external circuit the air velocity can be greatly reduced from 45-65 m/s. to 30-45 m/s to allow material larger than 10 mm to fall through the ring and fed back to the mill at the top along with fresh feed. This reduces pressure drop to about 400 mmwc reducing fan power by a corresponding amount.

The mill is started either with the rollers in lifted-up position, or with the hydro-pneumatic system at low pressure. In grinding mode, actual metal to metal contact should be prevented by limit switches or a mechanical stop and by consistent feed. In VRMs the material cycle time is usually less than a minute against several minutes for a ball mill or tube mill. Thus, control response should be accordingly faster. In case mill feed fails action should be taken within no more than 45 seconds or excessive vibration will cause mill shut-down. Moreover, the vertical mills are subject to vibrations if material is too dry to form a stable bed. Therefore, provision is made for controlled spray water inside the mill During mill operation magnetic separator and metal detector should be always functional to ensure to exclude tramp metal which can damage the grinding surfaces.

Primary roller mill controls are:

Mill drive power or mill differential pressure to control mill feed rate.

Inlet gas temperature.

Outlet gas temperature.

Outlet gas flow.

Few countable salient Features of Vertical Mills

- They are air swept mills, therefore has a higher drying capacity to handle an aggregate moisture of up to 20% in raw materials.

- Space needed for vertical mill is much less than a closed circuit ball mill of same capacity.

- As separator is integral part of the mill itself, the number of auxiliary equipments are less.

- Total power consumption for grinding circuit as a whole is also less by about 30% compared to closed circuit ball mill in spite of higher fan power.

- Feed size can be as large as 75 to 100 mm. Feed size can be as large as 5% of roller diameter.

Roller Press. Roller press consists of two rollers lined with wear resistant material. One roller is fixed and the other one is movable to exert pressure, applied hydraulically. A roller press looks similar to a roll crusher. However, the pressure exerted between rollers is very high - of the order of 400 kg/cm2 as compared to roll crushers. Feed is fed over the total width of the rollers by a central chute. About 30 % material gets pulverized to the required product fineness. Pressed material comes out as cake. This cake is divided into middle fraction containing more fines and coarse end fractions. End fractions are sent back to the roll press for re-crushing.

There are various ways in which the roller press can be used in the system.

As a pre-crusher in open circuit. Roller press cake is fed to a ball mill operating in closed circuit. Mill separator circuit is the usual dry closed circuit grinding system. However, mill is much smaller in size and larger grinding balls are no more required.

In 'hybrid' grinding circuit. In it both the roller press and the mill operates in closed circuit. Output o roller press is sent to a classifier and coarse fraction returned to it. Thus end fractions are collected separately and fed back to roll press and only the middle fraction is sent to mill for further grinding.

Using press only as standalone pressing and grinding unit. In this circuit. Middle fraction is sent to a disagglomerator through which hot gases are passed for drying. Disagglomerator material is passed to high efficiency separator which returns a coarse fraction back to roller press for regrinding.

Separators

Several types of separator are employed in mill circuits and there are numerous variations of each type:

Grit separators. Grit separators are with air-sweep mills. It consists of adjustable vanes and central pipe in a cyclonic body. Separation takes place by the cyclonic air flow induced by guide vanes. Grit separators have no moving parts therefore, incurs least maintenance costs. These are suitable for mills of small capacities.

Mechanical separators Mill discharge material is fed onto a rotating dispersion plate whence it is spread off into a rising air stream. Coarse particles either fall directly from the dispersion plate or are rejected between the auxiliary fan blades and the control valve. Fine dust is taken along with main fan flow and is detrained as the gas flows downwards loses momentum (velocity) and diversion through the return vanes. Controlling parameters are the number of auxiliary blades, the clearance between auxiliary blades and control valve, and the radial position of the main fan blades

High efficiency separators, 3rd generation separators were introduced to improve

the mechanical separator's fines recovery efficiency. Examples of these separators are O-Sepa (FLSmidth), Sepol (ThyssenKrupp) A simplified process flow these separators is as follows. Material is fed onto a rotating dispersion plate via air slide, whence it is dispersed off into the classifying air stream. Separator loading is recommended to be up to about 2.5kg feed/M3 air flow. Vortex is formed by the rotor which classifies particles between centrifugal force and the inward air flow. The fine fraction exits upwards/downwards with the air sucked by ID fan passes through cyclone separators or a bag filter for product collection, while the coarse fraction falls and is discharged from the bottom and send back to mill for regrinding. Fineness is controlled by rotor speed (increasing speed increases fineness).

Dynamic classifiers: These are used integrally with a roller mill involve the upward flow of dust-entrained air into a separator above the grinding table where, coarse particles fall back to the mill table and fines leave with the exhaust gases for collection in cyclone or bag filter. With improved classifier efficiency (LV classifier) mill capacity has significantly enhanced along with further decrease in specific power consumption raw mills.